Piston Valve Applications: Kerosene Filling

M&M Piston actuated valves can be used in a wide variety of applications, in this next series of blog posts we are going to provide some examples of the type of applications that they have been used in and the type of valve that we would recommend for the application.

Piston actuated valves used in kerosene filling rigs:

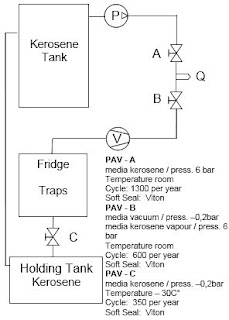

The equipment is used to fill thermic probes with kerosene. The system is made up of an injection unit, a cooling system, a vacuum pump, a pressure pump and a kerosene tank.

1st stage - vacuum

The probe is connected to the fast connection nozzle (Q). When the vacuum pump starts (V) valve (A) opens and creates a -0.2 bar depression inside the probe to prevent air bubbles from forming during filling operations.

2nd stage - Filling

Kerosene at room temperature contained in a tank is controlled by pump (P) and sent to the filling unit. Valve (A) closes and valves (B) opens to let kerosene into the probe. When it is full, the tightness of the probe is tested up to 6 bar pressure.

Piston actuated valves used in kerosene filling rigs:

The equipment is used to fill thermic probes with kerosene. The system is made up of an injection unit, a cooling system, a vacuum pump, a pressure pump and a kerosene tank.

1st stage - vacuum

The probe is connected to the fast connection nozzle (Q). When the vacuum pump starts (V) valve (A) opens and creates a -0.2 bar depression inside the probe to prevent air bubbles from forming during filling operations.

2nd stage - Filling

Kerosene at room temperature contained in a tank is controlled by pump (P) and sent to the filling unit. Valve (A) closes and valves (B) opens to let kerosene into the probe. When it is full, the tightness of the probe is tested up to 6 bar pressure.

3rd

stage – Exhaust of the injection unit

When filling is

over, the probe is disconnected from the injection unit, valve (B)

closes, valve (A) reopens and the vacuum pump (V) starts,

creating a depression inside the circuit. Kerosene left inside the unit is

sucked up and sent into a heat exchanger to be cooled up to –30° and brought

back to a liquid state. Valve (C) installed at the bottom of the heat

exchanger opens at the end of the day and kerosene exhausts into a collecting

tank. Kerosene is then carried back into the main tank.

The valve that we would recommend for this application is:

You can view the V-Flow Solutions range of M&M Piston actuated valves here:

V-Flow Solutions: Piston Valves

You can read the rest of V-Flows blogs here.

Technical Information

You can read the rest of V-Flows blogs here.

M&M Angle seat piston valves

M&M piston valves are highly recommended under these conditions:

M&M piston valves are manufactured in Italy, using the highest quality materials for a high quality product.

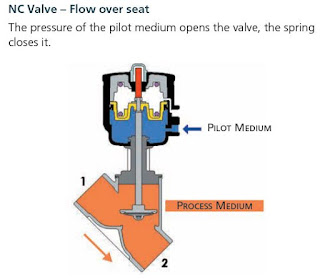

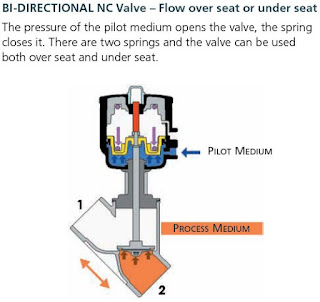

M&M piston actuated valves use an external control media to pilot the actuator, where a piston valve is directly connected to the main seal that closes onto the main orifice, thereby controlling the flow of liquids and gases.

- Media containing dirt particles

- Highly viscous media (up to 600 cST (80°E); 1 centistoke = 1 mm2/s)

- High flow volumes

- High temperatures

- Damp environments or hazardous locations

|

|

|

|

|

Technical Information

The main seal material used in piston actuated valves:

A modified PTFE has been used as the main seal material since 2004, when it replaced the original PTFE material seal.

The modified PTFE seal provides these benefits over the previous verision:

- Lower porosity and permeability

- Fewer void spaces

- Higher elasticity

- Reduced deformation under load

- Better chemical resistance to controlled media

- Smoother surface and improved design flexibility

The standard bonnet seals consist of 2 'V'-shaped FKM gaskets and a package of 25% graphite-filled PTFE gaskets.

High temperature Piston actuated valves:

M&M can offer a piston valve that can be used up to 200°C, provided that the valve pressure limits are respected.

The main differences, in regards to the materials in this design, are as follows:

The main differences, in regards to the materials in this design, are as follows:

- Change of the actuator material: From standard PA6 to PA66 filled with 30% fibreglass

- All valves with DN > 25 with fixed plug design (to withstand turbulence caused by steam at high speed)

- Special design of bonnet chevrons, all are made of 25% graphite-filled PTFE

10 Reasons to use a piston actuated valve:

----------------------------------------------------------------------------------------------------------------------------------------------

Piston actuated valves can be found here, on our website:

http://v-flowsolutions.co.uk/actuated-valves/pneumatic/piston-valves/

http://v-flowsolutions.co.uk/actuated-valves/pneumatic/piston-valves/

----------------------------------------------------------------------------------------------------------------------------------------------

If you think V-Flow can help you then please contact us:

If you think V-Flow can help you then please contact us:

Telephone: +44 (0)1234 855888

Email: sales@v-flowsolutions.co.uk

Fax: +44 (0)1234 857775

Comments

Post a Comment